hdpe pipe types

Product Description

https://www.pedredgepipe.com/resources/types-and-design-of-hdpe-pipes.html

Types and Design of HDPE Pipes

HDPE pipe is a flexible plastic pipe made of thermoplastic high-density polyethylene widely used for low-temperature fluid and gas transfer. In recent times, HDPE pipes got their extensive uses for carrying potable water, hazardous wastes, various gases, slurry, firewater, stormwater, etc. The strong molecular bond of HDPE pipe materials helps it to use for high-pressure pipelines. Polyethylene pipes have a long and distinguished service history for gas, oil, mining, water, and other industries. Due to its low weight and high corrosion resistance, the HDPE pipe industry is growing tremendously. In the year 1953, Karl Ziegler and Erhard Holzkamp discovered high-density polyethylene (HDPE). HDPE pipes can work satisfactorily in a wide temperature range of -2200 F to +1800 F. However, the use of HDPE Pipes is not suggested when the fluid temperature exceeds 1220 F (500 C).

Types of Pipes

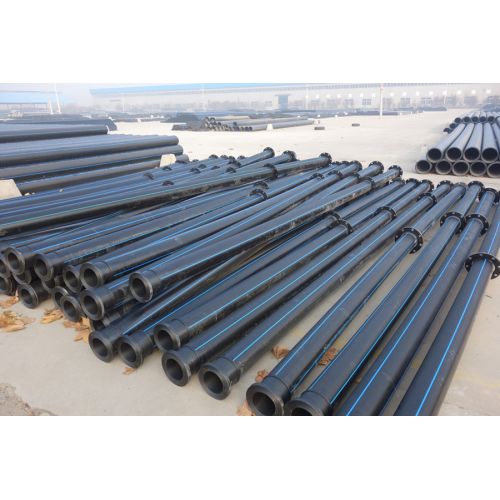

HDPE pipes are made by the polymerization of ethylene, a by-product of oil. Various additives (stabilizers, fillers, plasticizers, softeners, lubricants, colorants, flame retardants, blowing agents, crosslinking agents, ultraviolet degradable additives, etc.) are added to produce the final HDPE pipe and components. HDPE pipe lengths are made by heating the HDPE resin. It is then extruded through a die, which determines the diameter of the pipeline. The Pipe wall thickness is determined by a combination of the die size, the speed of the screw, and the speed of the haul-off tractor. Usually, 3-5% carbon black is added to HDPE to make it UV resistant, which turns HDPE pipes black in color. Other color variants are available but usually not used frequently. Colored or striped HDPE pipe is usually 90-95% black material, where a colored stripe is provided on 5% of the outside surface.

Properties of HDPE Pipes

The physical and mechanical properties of a typical HDPE Pipe are listed below:

Governing Codes: ISO 1183, ISO 4427, AS/ NZS 4130, BS EN 12201, EN 12056, AWWA C901, AWWA C906, etc

Available size range: DN 16 to 1600 (However, other customized sizes can be manufactured)

The density of HDPE Pipe: 930-970 kg/m3

Typical Mechanical Properties of HDPE Pipe are given in Table 1 below. However, these values vary from one manufacturer to another. So, must be consulted with the manufacturer.

Mechanical PropertiesHDPE PropertiesYield Strength18-26 MpaElongation10%Elastic Modulus900 MpaHardness61 Rockwell (Shore)Poisson’s Ratio0.45Linear Coefficient of thermal expansion0.17 mm/m-0CBrittleness temperature<-700CTable 1: Mechanical Properties of HDPE Pipe