custom aluminum extrusion profiles

Product Description

https://www.gdcoyo.com/recommend-products/custom-aluminum-extrusion-profiles.html

Custom Aluminum Extrusion Profiles

Custom Aluminum Extrusion Profiles

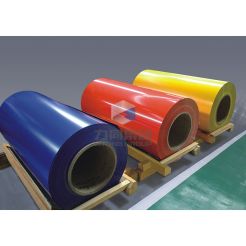

At Coyo, we focus on working with our customers to develop cost-effective engineered materials solutions. Our ability to supply a wide range of custom aluminum profiles means you have a virtual one-stop source for machined, painted and anodized products.

Our experienced team of extrusion experts will work with you to design the best engineered solutions for applications in markets such as construction, construction, energy, electrical industrial equipment, lighting and various consumer durables markets.

Working principle: Aluminum extrusion process

Aluminum extrusion is a versatile, heat-dependent process used to shape aluminum alloys into unique cross-sectional profiles. T-slot aluminum and aluminum angles are the two most common aluminum extrusions, but custom molds can be created for unique applications.

Choosing the right extruded aluminum alloy

When selecting the type of aluminum alloy for extrusion, formability and workability, weldability, machinability, corrosion resistance, heat treatability, material strength and end-use application must be considered.

Alloy 1000 Series

This series is an excellent choice for applications requiring high formability, weldability, and corrosion resistance. However, the 1000 series does not respond well to heat treatment and has low strength. Typical uses include metal spinning and general fabrication.

Alloy 2000 Series

The 2000 series, on the other hand, offers high strength. The grades within this series are often used in the production of complex parts, since the 2000 series offers a high degree of machinability. Also, its strength-to-weight ratio makes it ideal for aerospace applications. However, these aluminum alloys provide low weldability and corrosion resistance.

Alloy 3000 Series

The 3000 series is the most popular. These alloys contain manganese and aluminum that is 20% stronger than the 1000 series while still maintaining commercial purity. The 3000 Series is commonly used in equipment in the food and chemical industries as well as general manufacturing.

Alloy 5000 Series

The 5000 series is most commonly used in marine environments due to its extremely high corrosion resistance. These alloys are unresponsive to heat treatment but possess a considerable degree of weldability, formability, and strength.

Alloy 6000 Series

Series 6000 is most commonly used in structural and construction environments because of its ease of welding. It can also be anodized, allowing for a variety of surface finishes. This series is typically used in hardware and coupling applications.