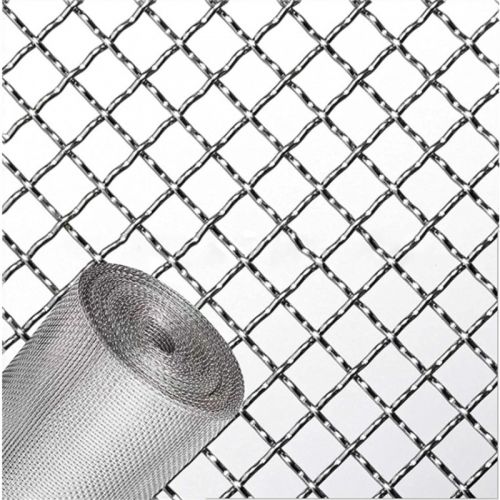

crimped wire mesh

Product Description

https://www.sswiremeshes.com/crimped-wire-mesh/

The crimped wire mesh is woven by pre-crimped metal wires through the method of double crimp or lock crimp. Crimped wire mesh is also called crimped woven wire mesh, The pre-crimping weaving method can ensure an accurate opening area and make the structure stable. Crimped mesh can also be used in the food industry and industrial applications. Lightweight crimped mesh can be used as barbecue grill mesh, stair railings, fences, construction grilles, and decorations.

Crimped wire mesh commonly used in industries with strict requirements on stability. For example, the food industry is used as a net basket for food, and the chemical industry is used for screening and filtering in acid and alkali environments. Electroplating industry is used as pickling net, petroleum industry as mud net, architectural decoration as decorative net, oil-water separator in automobile industry, etc. Stainless steel has been widely used in mining, chemical industry, medicine, petroleum, metallurgy, machinery, protection, construction, handicrafts and other industries in crimped wire mesh.

Wire Mesh Weave Styles

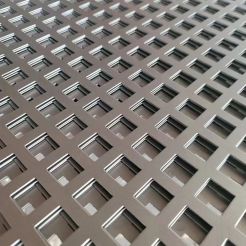

Wire mesh weave styles refer to the different patterns created by interweaving wires in a mesh fabric. Some common wire mesh weave styles include:

Plain weave: This is the most common and simplest type of weave, where the wires are interwoven in an alternating over-under pattern.

Twill weave: This weave has a diagonal pattern created by passing the wire over two or more weft wires and then under one or more weft wires.

Dutch weave: This is a tight weave where the weft wires are closely spaced together, and the warp wires are relatively large in diameter. This creates a strong and durable mesh that is often used for filtration.

Reverse Dutch weave: This is similar to the Dutch weave, but the positions of the warp and weft wires are reversed. The warp wires are closely spaced together, and the weft wires are relatively large in diameter. This weave creates a high-strength mesh that is often used for industrial applications.

Twilled Dutch weave: This is a combination of twill weave and Dutch weave. The weft wires are closely spaced together, and the warp wires are relatively large in diameter. The pattern created by this weave is strong and dense, making it ideal for filtration and separation.

Plain Dutch weave: This is similar to the Dutch weave, but with a larger warp wire diameter and a smaller weft wire diameter. This creates a fine mesh that is often used for filtration and sieving applications.

Crimped weave: This is a weave where the wires are crimped before weaving to create a wavy pattern. This creates a more flexible mesh that is often used for architectural and decorative applications.