Automatic lithium battery pack production line

An automatic lithium battery pack production line is a facility equipped with specialized machinery and automated processes designed to manufacture lithium-ion battery packs.

Product Description

1. Introduction of Automatic Lithium Battery Pack Production Line

An automatic lithium battery pack production line is a facility equipped with specialized machinery and automated processes designed to manufacture lithium-ion battery packs. This assembly line is specifically tailored for the efficient, high-volume production of these battery packs, which are commonly used in various applications such as electric vehicles, portable electronics, and energy storage systems.

The production line involves a series of automated steps that encompass the assembly of individual components, testing, quality control, and packaging. The machinery and processes used are designed to handle the precise assembly of lithium-ion cells, battery modules, and the integration of components like Battery Management Systems (BMS) into these modules. The line ensures that each step of the battery pack assembly is performed accurately and consistently to meet quality standards and industry specifications.

Our Lithium Battery Production Line stands as a testament to our commitment to advancing manufacturing technology and reshaping the landscape of battery production. From concept to execution, every element of this automated production line is meticulously engineered to revolutionize PACK manufacturing and empower businesses to thrive in a fiercely competitive market.

2. Technical Highlight of Automatic Lithium Battery Pack Production Line

► Unparalleled Efficiency: Time is of the essence in battery PACK production. Yao Laser's battery pack automation production line is purpose-built for unrivaled efficiency, minimizing cycle times, and maximizing production output. Automated processes, seamless workflow integration, and real-time data management ensure optimum productivity.

► Precision and Reliability: Precision is the bedrock of exceptional PACK manufacturing. Our production line leverages cutting-edge laser technology and advanced robotics for precise assembly, welding, and quality control of battery PACK components. The result is PACKs that exemplify top-tier performance and durability.

► Versatility and Customization: Acknowledging the diverse spectrum of battery applications, our Automation Production Line offers adaptability and customization. It accommodates various PACK designs, sizes, and specifications, catering to the unique needs of electric vehicles, energy storage systems, and beyond.

► Seamless Automation and Intelligent Control: The integration of machinery and automation systems fosters a seamless and intelligent production line. Our smart automation solutions optimize process control, minimize downtime, and enhance resource utilization, all while reducing reliance on manual intervention.

► Safety and Sustainability: We prioritize the safety of our operators and the environment. The production line is equipped with advanced safety features, adhering to the highest global safety standards. Additionally, our commitment to sustainability shines through in the production line's energy-efficient design and eco-friendly practices.

► With a legacy of innovation and an unwavering pursuit of excellence, HuiYao Laser Battery PACK Automation Production Line stands at the forefront of battery manufacturing evolution. Embrace the power of automation and advanced manufacturing, elevating your battery PACK production capabilities to new horizons.

► Join us in shaping a future of sustainable energy solutions, driving progress, and making a positive impact on the world with huiYao Laser's Battery PACK Automation Production Line.

3. Technical Parameters of Automatic Lithium Battery Pack Production Line

► Equipment production capacity greater than or equal to 6-12PPM .

► Final yield rate greater than or equal to 99.8%

► Equipment failure rate less than or equal to 2%.

► Cell Size Range: Customized according to requirements

► Blueprint Battery Cell: 280AH Battery Cell

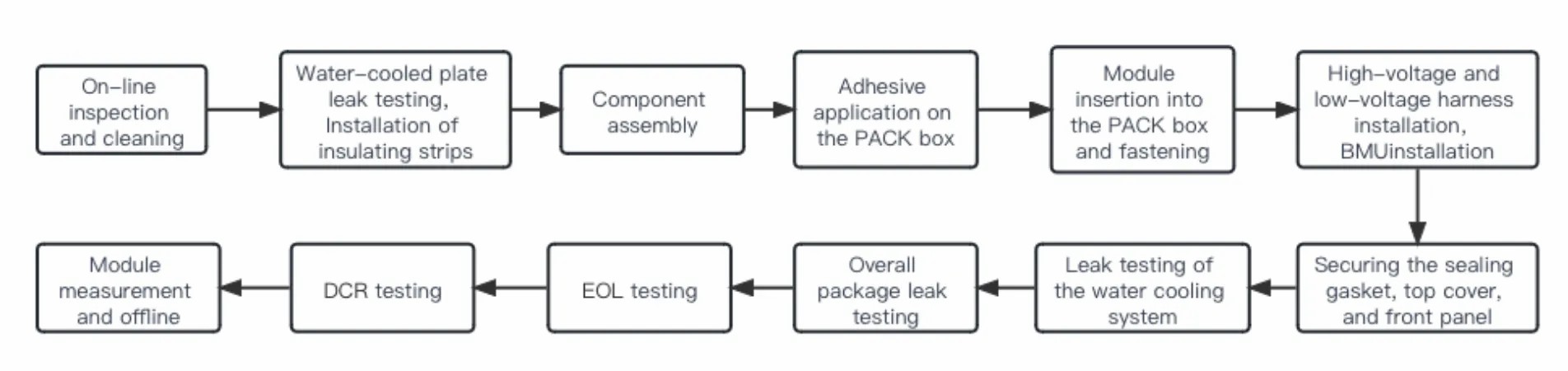

4.Process Flow

4.1 Cell Automatic Loading Station