test bench for valves

Product Description

https://www.suncenterbooster.com/products/breather-vacuum-relief.html

Breather Vacuum Relief Valves Test Bench

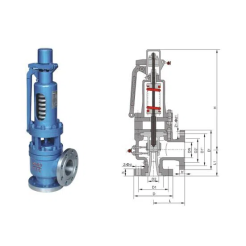

Breather Valves, also known as direct acting Pressure/Vacuum Relief Valves, are special types of Relief Valves which are specifically designed for tank protection.

MOQ: 1 Set

Brand Name: SUNCENTER

Certificate: ISO/CE/SGS

Warranty: 13 Months

Packaging: by Plywood case

Shipping Port: Shenzhen/Hongkong

Payment: T/T, Western Union, Credit card.

Transaction method: EXW, FOB, DDP, CIF, CFR

Place of Origin: Guangdong Province, China (Mainland)

Delivery Time: Within 10-15 working days after received deposit.

1. Breather valve test bench introduction

Breather Valves, also known as direct acting Pressure/Vacuum Relief Valves, are special types of Relief Valves which are specifically designed for tank protection. It is a kind of safety protection device for transportation and storage of petroleum, chemical, natural gas, shipping and other industrial oil and flammable and explosive substances

The correctness and reliability of its performance are directly related to the safety of the transportation and storage of oil and flammable and explosive substances, which is related to the safety of life and property. The State Bureau of technical supervision is mandatory; all the enterprises and units that use the breathing valve must regularly check the performance parameters of the valve. Calibration is the main test items and means of the respiratory valve manufacturer factory test and the use of units to maintain the respiratory valve. Breathing valve calibration equipment is a manufacturer of respiratory valve and the use of essential equipment units.

2. System technical parameters and composition

a. medium: nitrogen N2 or air (compressed, filtered and dried).

b. the maximum output pressure is less than 0.8Mpa.

c. Suction pressure range:0-20 psi

d.Exhalation pressure(Vacuum ranges):-20psi-0

e. clamping range (the diameter of the valve flange): DN15-DN300(1”-12”)

f. power supply: 220V, 50HZ.

i. environment temperature: -20℃~+60℃

Working Principle

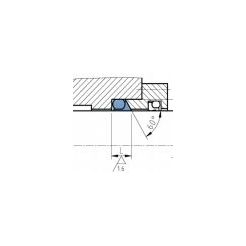

a. fixed the breathing valve to allow the media to enter or suck out the inlet of the check valve. Medium pressure to rise (or fall) to the call (suction) valve open state, measured at this time the pressure value, that is, open pressure calibration.

b. is composed of gas source, automatic clamping platform and testing console.

c. gas source:The utility model is composed of a nitrogen gas cylinder, a vacuum pump, a pressure reducing valve, a pressure gauge, an electromagnetic valve, an energy storage tank and a water splitting gas filter.

d. automatic clamping table: the pneumatic clamping device and clamping pedestal etc..

e. detection console: the electric contact pressure gauge, pressure control device, buttons, switches, solenoid valves, inductive sensors, relays, vacuum pumps, pneumatic systems, etc..